We spend a lot of time considering how we can improve our COTS qualification kits to be more useful to our customers. We believe that certain key factors can really drive efficiency and that the ideal qualification kit should:

- Be customized to support the user’s needs

- Include content that is understandable to all stakeholders

- Provide clear instructions on how to use and update the included documents

- Include cross-references from user and developer documents to each other and to the standards

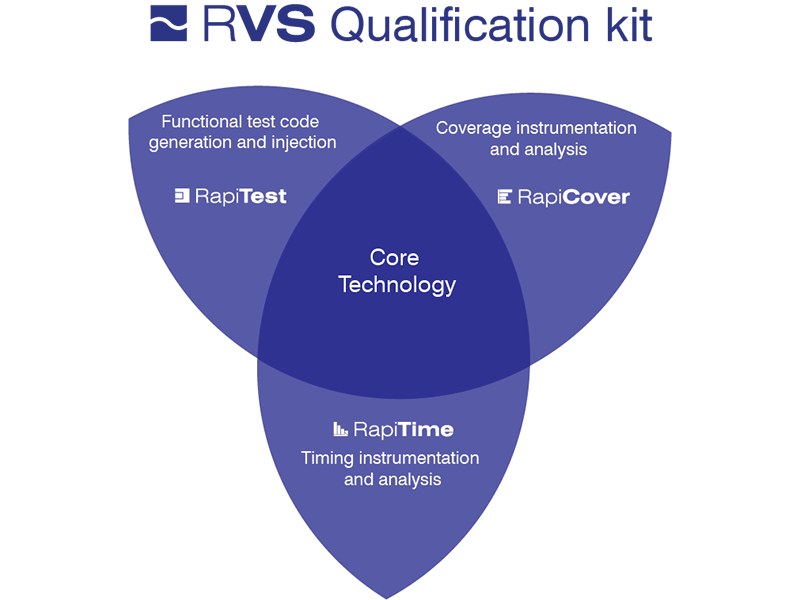

A good qualification kit should reduce review effort. One of the ways this can be done is by the kit’s contents being customized to the specific needs of each user, including applicable standards and guidance, products to be qualified and programming language(s) used in the project. While information about timing analysis may be very interesting, it won’t help when qualifying a tool for structural coverage – on the contrary, it would just delay your review process. Similarly, if you only use Ada, information about how the tool you’re qualifying works with C or C++ is informative but not directly useful. Because of this, we customize the information in our generic qualification kits by standard and product, and optionally by source language (including an option for projects using multiple languages). To further reduce review effort needed, we have plans to streamline our qualification kits in the future to cover the types of instrumentation applied (e.g. statement, decision and MC/DC coverage instrumentation) and specific options used.

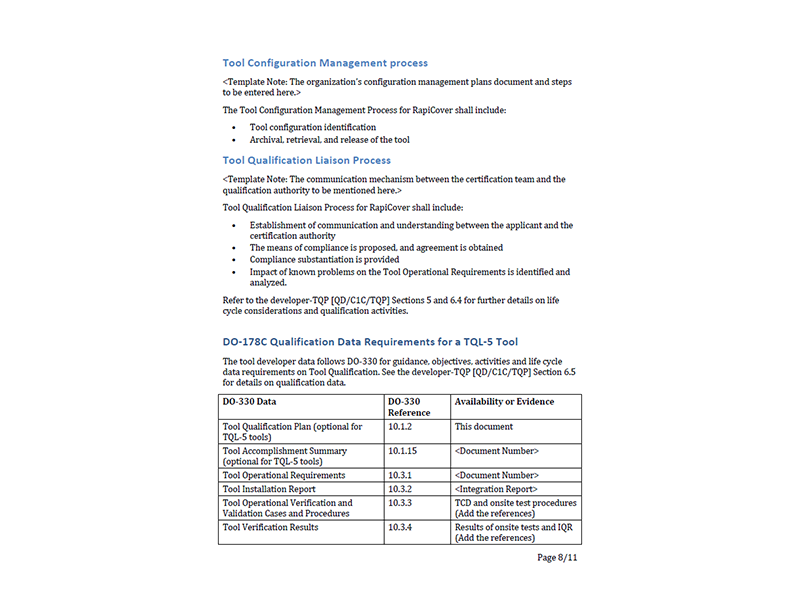

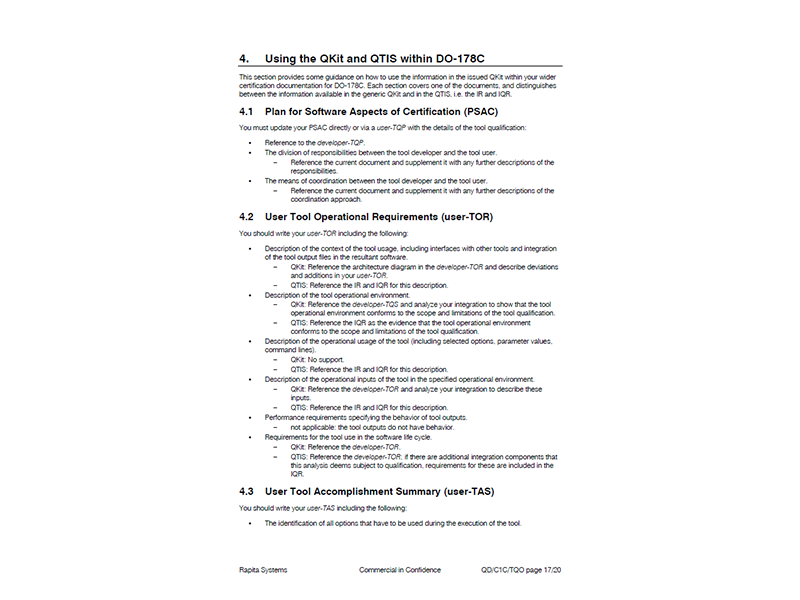

For successful qualification, both tool users and certification authorities will need to understand the contents of qualification kits, so these contents should be as clear and understandable as possible. Any misunderstandings may result in more effort being needed and put the qualification (and possibly certification) schedule at risk. To ensure that all stakeholders can understand the content in R VS qualification kits, we map document headings to, and include clear cross references to, the actual standards, and keep the language used simple and straightforward.

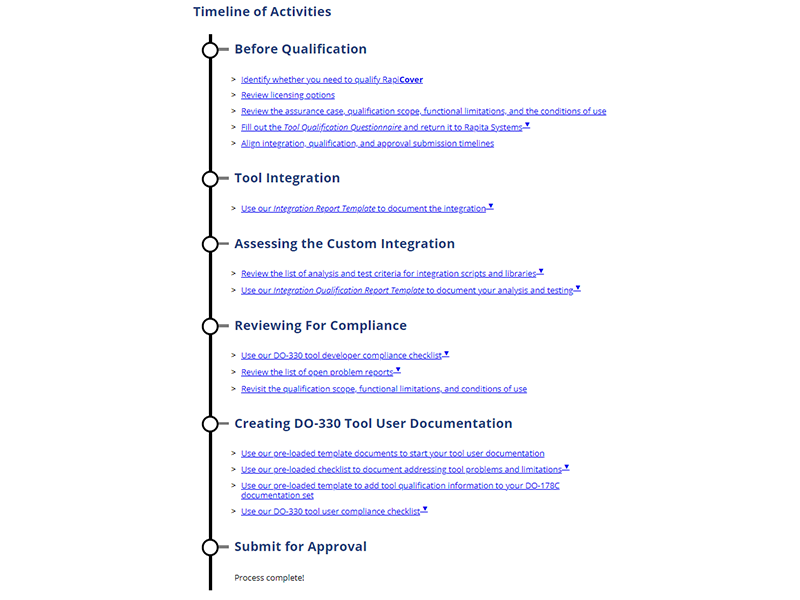

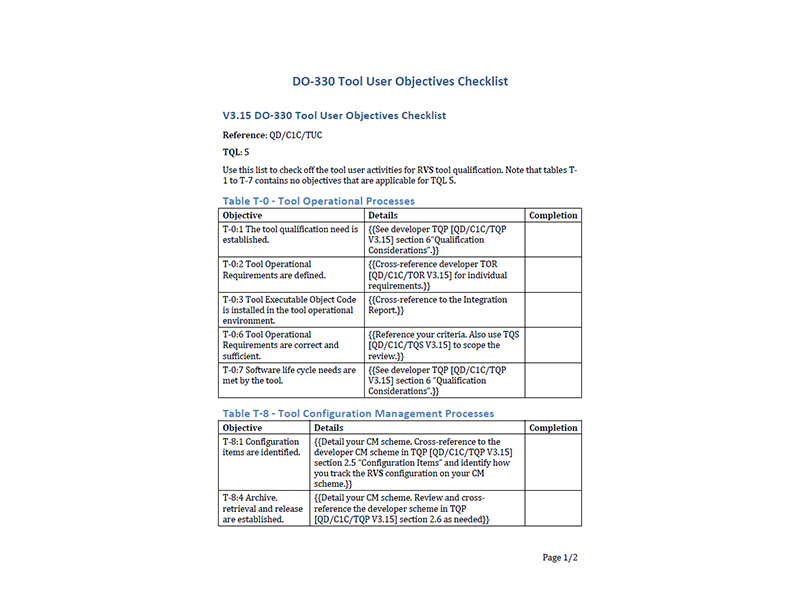

The efficiency of tool qualification depends on how well the qualification process and what is needed at each stage is understood. To ensure that our qualification kits and the process are understood, we make our qualification kits easy to use by including a timeline of the stages in tool qualification, a detailed breakdown of what must be done in each stage, by including checklists that help users track their progress, and by including template tool user documents to help users complete their required tool user activities.

When delivering tool qualification evidence to a certification authority, you’ll need to ensure that relevant documents are cross-referenced both within your qualification evidence and to external documents. A good qualification kit will include these cross-references as standard, so you don’t need to add them yourselves. Our R VS qualification kits include internal references between related developer and user documents, and references to the standards and guidance addressed (e.g. DO-178B, DO-178C and ISO 26262).

We take tool qualification very seriously and pride ourselves on providing an accessible qualification kit that helps our users through the qualification process. For more information on our tool qualification, see our Qualification page. To request to see a sample of our qualification kits, contact us at info@rapitasystems.com.

Rapita System Announces New Distribution Partnership with COONTEC

Rapita System Announces New Distribution Partnership with COONTEC

Rapita partners with Asterios Technologies to deliver solutions in multicore certification

Rapita partners with Asterios Technologies to deliver solutions in multicore certification

SAIF Autonomy to use RVS to verify their groundbreaking AI platform

SAIF Autonomy to use RVS to verify their groundbreaking AI platform

RVS gets a new timing analysis engine

RVS gets a new timing analysis engine

How to measure stack usage through stack painting with RapiTest

How to measure stack usage through stack painting with RapiTest

What does AMACC Rev B mean for multicore certification?

What does AMACC Rev B mean for multicore certification?

How emulation can reduce avionics verification costs: Sim68020

How emulation can reduce avionics verification costs: Sim68020

How to achieve multicore DO-178C certification with Rapita Systems

How to achieve multicore DO-178C certification with Rapita Systems

How to achieve DO-178C certification with Rapita Systems

How to achieve DO-178C certification with Rapita Systems

Certifying Unmanned Aircraft Systems

Certifying Unmanned Aircraft Systems

DO-278A Guidance: Introduction to RTCA DO-278 approval

DO-278A Guidance: Introduction to RTCA DO-278 approval

The EVTOL Show

The EVTOL Show

NXP's MultiCore for Avionics (MCFA) Conference

NXP's MultiCore for Avionics (MCFA) Conference

Embedded World 2026

Embedded World 2026

XPONENTIAL 2026

XPONENTIAL 2026