DO-178

RTCA DO-178C / EUROCAE ED-12C: Software Considerations in Airborne Systems and Equipment Certification is the primary document by which certification authorities such as the FAA and EASA approve civil software-based aerospace systems. Recently, it has become the de facto approach for demonstrating airworthiness in military avionics systems worldwide.

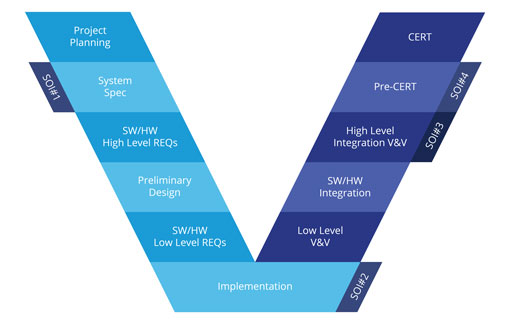

Introduction to DO-178C

DO-178 was originally developed in the late 1970s to define a prescriptive set of design assurance processes for airborne software that focused on documentation and testing. In the 1980s, DO-178 was updated to DO-178A, which suggested different levels of activities dependent on the criticality of the software, but the process remained prescriptive.

Released in 1992, DO-178B was a total re-write of DO-178 to move away from the prescriptive process approach and define a set of activities and associated objectives that a design assurance process must meet. This update allowed flexibility in the development approaches that could be followed, but also specified fundamental attributes that a design assurance process must have, which were derived from the airworthiness regulations.

Many advances in software engineering technologies and methodologies since the release of DO-178B made consistent application of the DO-178 objectives difficult. In 2012, DO-178C/ED-12C was released, which clarified details and removed inconsistencies from DO-178B, and which also includes supplements that provide guidance for design assurance when specific technologies are used, supporting a more consistent approach to compliance for software developers using these technologies. DO-178C guidance also clarified some details within DO-178B so that the original intent could be better understood and more accurately met by developers.

Collins Aerospace

How RapiCover was used for DAL A code coverage analysis for a complex flight control system.

Triumph Group

How Rapita's V&V services produced evidence for certification of actuation system software.

Cobham Aerospace

Rapita tools efficiently produced coverage evidence for DAL C certification of an antenna control unit.

OHB Sweden

How Rapi Cover improved code coveage analysis for DO-178C attitude orbital control system.

Design Assurance Levels

DO-178B introduced (and DO-178C continued to use) the fundamental concept of the Design Assurance Level (DAL), which defines the amount of rigor that should be applied by the design assurance process based on the contribution to Aircraft Safety. The higher the DAL, the more activities and objectives that must be performed and met as part of the Design Assurance process because of the more severe consequences to the aircraft should the software fail or malfunction.

|

DAL |

Condition |

Objectives |

|---|---|---|

|

A |

Catastrophic |

71 |

|

B |

Hazardous |

69 |

|

C |

Major |

62 |

|

D |

Minor |

26 |

|

E |

No safety effects |

0 |

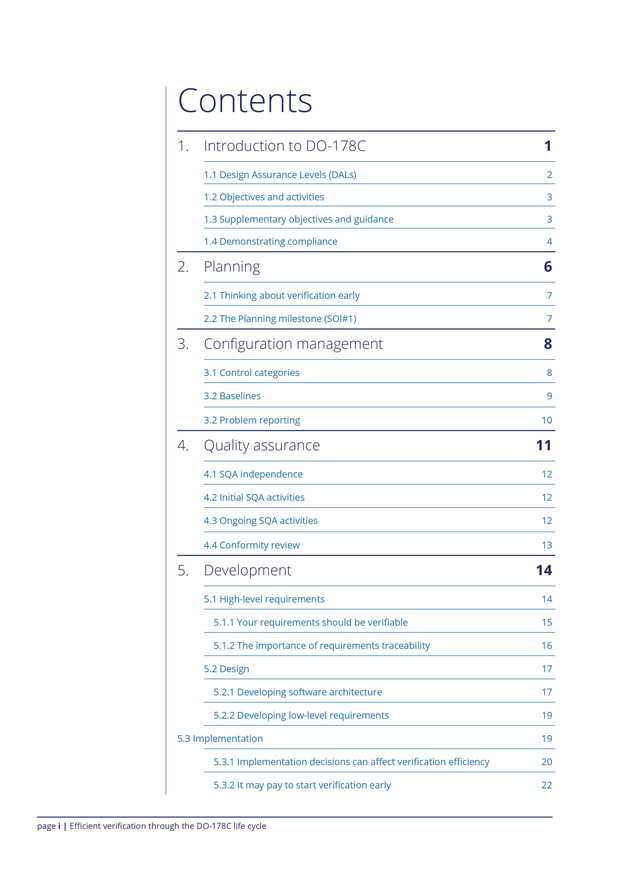

Efficient verification through the DO-178C life cycle

This handbook takes you through the whole DO-178C journey with a focus on verification, leaving you with an understanding of the compliance process as a whole and practical tips to efficiently verify DO-178C software.

Tool qualification

As per DO-178C, you need to qualify any software tool you use that replaces or mitigates any DO-178C process and for which the output is not manually verified. The qualification process ensures that such software tools can be relied upon to produce appropriate and repeatable results.

DO-178C itself describes when a tool must be qualified, but does not go into detail on how this should be done. The DO-330: Software Tool Qualification Considerations supplement to DO-178C expands on this guidance by defining corresponding objectives for the specification, development and verification of qualified tools.

If you use any commercial verification tools to automate DO-178C verification processes and don’t plan on manually reviewing output from the tools, they will need to be qualified at the appropriate tool qualification level. Many commercial verification tools have supporting qualification kits, which include evidence needed to demonstrate that the activities the tool developer must perform have been performed. All qualification kits should include all of the evidence needed from the tool developer. Some qualification kits may also include supporting material to help meet tool user objectives.

How can Rapita help?

The Rapita Verification Suite (R VS) reduces the effort needed to verify DO-178C software by helping to satisfy specific DO-178C objectives.

R VS includes plugins that satisfy requirements-based functional testing, structural coverage analysis and worst-case execution time analysis and is supported by a qualification kit and service to provide DO-330 tool qualification evidence.

To see how R VS could help you, contact us or download a free trial today.

Our Verification and Validation Services help satisfy DO-178C objectives. We provide services covering the full DO-178C life cycle, supporting efficient Planning, Development, and Integral processes including software verification using R VS. Our engineering team have diverse experience working in civil and defense avionics development and verification worldwide.

To see how our V&V Services could help you, download our brochure or contact us.

Our systems engineering services, with our emphasis on quality and adherence to ARP4754A industry guidance, support the development of systems with well-designed hardware and software.

We support system integration and verification and validation of system requirements. Our automated V&V tools integrate with industry standard requirements management software to capture results while seamlessly maintaining traceability to requirements. Find out more about our systems engineering services.

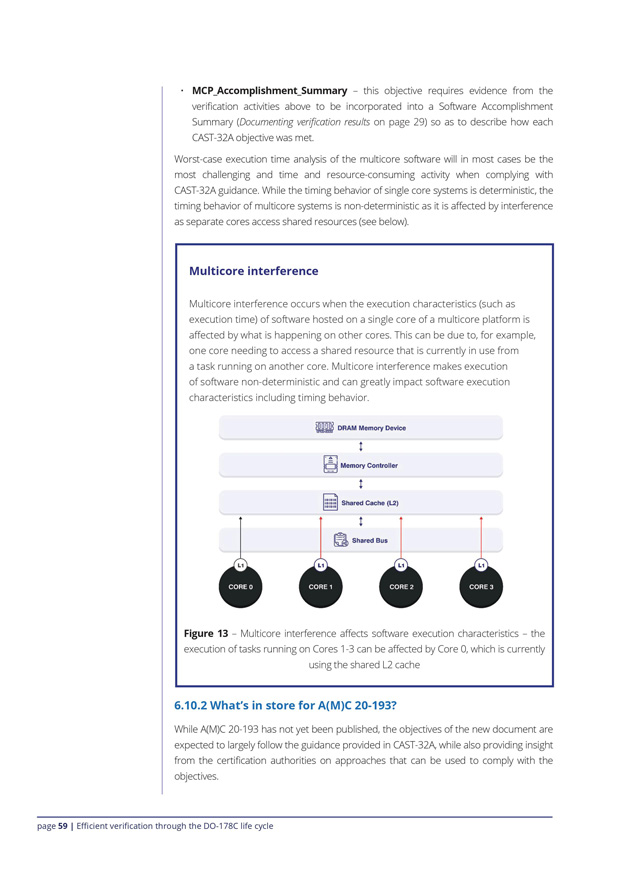

Specific guidance for how DO-178C should be applied to multicore software is available in the A(M)C 20-193 guidance.

MACH 178 supports Planning, Development and Integral processes for multicore DO-178C projects, including by support multicore timing analysis, which is widely considered to be the most challenging element of A(M)C 20-193 compliance. To see how MACH 178 could help you, contact us.

Our support team is comprised of our Field Application Engineers (FAEs), who use RVS every day and regularly perform integrations involving a variety of compilers, languages, and platforms.

Our policy is to always provide our customers with the best level of support we can realistically achieve, and as such we resolve support issues as quickly and effectively as we can. We have a strong history of excellent support and regard this as an essential aspect of our business. For more information on our support service, see our Support web page.

We provide training in a range of expert topics, including: DO-178C compliance, Multicore certification and setting up automated test environments.

Our training is flexible; we offer both face-to-face and virtual training and offer custom training courses to meet your specific needs.

For more information on our training solutions, see our Training web page.

DO-178C handbook preview

Read the first chapter

The safety assessment processes used in all functional safety domains rely on demonstrating that the probability of system failure that could cause harm is below an acceptable threshold.

When a system is made up of mechanical and electronic components, for which the component failure rate is known, the probability of failure for the system can be calculated and achievement of the safety target can be demonstrated. For software, complex systems or electronic hardware, system failures can be caused by design errors (sometimes known as systematic failures) as well as component failures, but there is no agreed way of calculating the failure rate of these design errors. In the aerospace domain, the agreed approach for dealing with design errors is to implement design assurance processes that have specific activities to identify and eliminate design errors throughout the software development life cycle.

DO-178 was originally developed in the late 1970s to define a prescriptive set of design assurance processes for airborne software that focused on documentation and testing.

Design Assurance Levels (DALs)

DO-178B introduced (and DO-178C continued to use) the fundamental concept of the Design Assurance Level (DAL), which defines the amount of rigor that should be applied by the design assurance process based on the contribution to Aircraft Safety. The higher the DAL, the more activities and objectives that must be performed and met as part of the Design Assurance process because of the more severe consequences to the aircraft should the software fail or malfunction. Design Assurance Level A (DAL-A) is the highest level of design assurance that can be applied to airborne software and is applied when failure or malfunction of the software could contribute to a catastrophic failure of the aircraft. The activities and objectives that must be met through the Design Assurance process gradually decrease with each level alphabetically until DAL-E, which has no objectives as there is no consequence to aircraft safety should such software fail or malfunction.

Objectives and activities

The recommendations given in DO-178 fall into two types:

- Objectives, which are process requirements that should be met in order to demonstrate compliance to regulations

- Activities, which are tasks that provide the means of meeting objectives

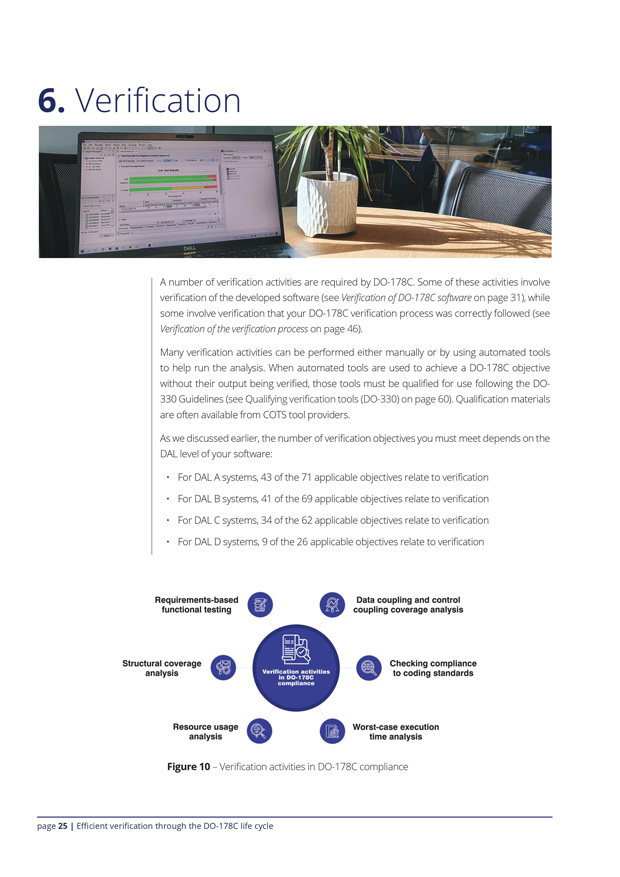

In total, DO-178C includes 71 objectives, 43 of which are related to verification. The number of these objectives that must be met for compliance reduces as the Design Assurance Level of the system reduces.

Supplementary objectives and guidance

DO-178C introduced three technology supplements to provide an interpretation of the DO-178C activities and objectives in the context of using specific technologies. The three technologies are Model Based Development and Verification (DO-331), Object Oriented Technology and related technologies (DO-332), and Formal Methods (DO-333). Each supplement describes the technology, defines the scope of its use within airborne software, lists additional or alternative activities and objectives that must be met when the technology is used, and includes specific FAQs (Frequently Asked Questions) that clarify objectives and activities relating to the technology.

A further supplement was introduced in DO-178C, Software Tool Qualification Considerations (DO-330), which gives guidance on the qualification of tools used in software development and verification processes. This guidance can be applied to any tools, not just those used for software development or verification, for example systems design or hardware development tools, and acts more like a stand-alone guidance document than the other supplements mentioned.

Many other documents support DO-178C by providing additional clarification or explanations that can help developers to correctly interpret the guidance and implement appropriate design assurance processes. The Supporting Information (DO-248C) supplementary document includes FAQs relating to DO-178C, and the document is commonly referred to by the title Frequently Asked Questions. In addition to the FAQs in DO-248C, the document provides the rationale for the activities and objectives listed in DO-178C and includes discussion papers that provide clarification on specific topics related to software development and verification. A series of documents produced by the Certification Authorities Software Team (CAST) since the release of DO-178B provided information on specific topics of concern to certification authorities in order to harmonize approaches to compliance. These topics have had a greater scope than just Software concerns, and much of the content in CAST documents has been implemented in guidance updates such as DO-178C, or formed the basis of authority publications, such as A(M)C 20-193 to address the use of multicore processors in avionics and A(M)C 20-152A on the development of airborne electronics hardware. CAST has remained inactive since October 2016 and links to most previous CAST papers have been removed from the FAA’s website...........

RVS 3.24 accelerates multicore software verification

RVS 3.24 accelerates multicore software verification

Rapita Systems and Avionyx Announce Strategic Partnership to Offer Best-in-class Avionics Solutions

Rapita Systems and Avionyx Announce Strategic Partnership to Offer Best-in-class Avionics Solutions

Rapita System Announces New Distribution Partnership with COONTEC

Rapita System Announces New Distribution Partnership with COONTEC

RVS gets a new timing analysis engine

RVS gets a new timing analysis engine

How to measure stack usage through stack painting with RapiTest

How to measure stack usage through stack painting with RapiTest

What does AMACC Rev B mean for multicore certification?

What does AMACC Rev B mean for multicore certification?

How emulation can reduce avionics verification costs: Sim68020

How emulation can reduce avionics verification costs: Sim68020

How to achieve multicore DO-178C certification with Rapita Systems

How to achieve multicore DO-178C certification with Rapita Systems

How to achieve DO-178C certification with Rapita Systems

How to achieve DO-178C certification with Rapita Systems

Certifying Unmanned Aircraft Systems

Certifying Unmanned Aircraft Systems

DO-278A Guidance: Introduction to RTCA DO-278 approval

DO-278A Guidance: Introduction to RTCA DO-278 approval

Embedded World 2026

Embedded World 2026

Test what you fly - Real code, Real Conditions Webinar

Test what you fly - Real code, Real Conditions Webinar

Avionics Certification Q&A: CERT TALK

Avionics Certification Q&A: CERT TALK

XPONENTIAL 2026

XPONENTIAL 2026